High water retention HPMC for dry-mix mortars

High water retention HPMC for dry-mix mortars

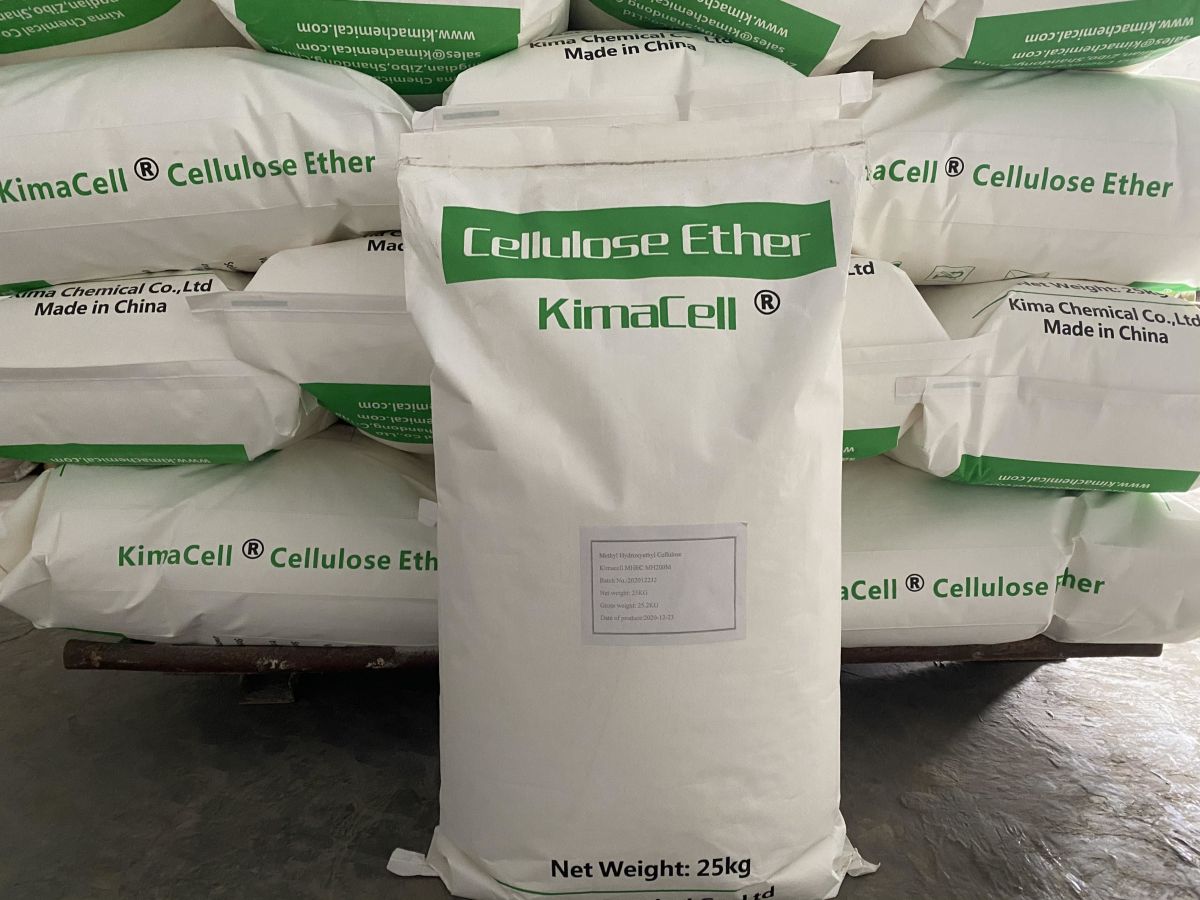

HPMC (Hydroxypropyl Methyl Cellulose) is a common additive in dry-mix mortars, including tile adhesives, cement-based renders, and other building materials. It acts as a water retaining agent and thickener, improving the workability and performance of mortar.

To enhance the water retention of dry-mix mortars, you can choose HPMC grades with high water retention capacity. These grades are usually marked with a higher viscosity number. The higher the viscosity, the better the water retention performance.

When selecting HPMC for high water retention in dry-mix mortars, consider the following:

Viscosity: Look for HPMC grades with high viscosity. Viscosity is usually expressed in numbers such as 4,000, 10,000 or 20,000 cps (centipoise). Higher viscosity grades tend to have better water retention properties.

Particle Size: Consider the particle size distribution of HPMC powders. Finer particles tend to have better dispersibility and water retention capacity, thus increasing water retention in mortars.

Compatibility: Make sure the HPMC grade you choose is compatible with the other ingredients of your dry-mix mortar formulation. It should disperse easily and mix well with the other ingredients without having any adverse effect on the properties of the mortar.

Application characteristics: Different types of dry-mixed mortar may have specific requirements for water retention. For example, tile adhesives may require different water retention properties than cement-based plasters. When selecting an HPMC grade, consider specific application requirements.

Manufacturer’s Recommendations: Follow manufacturer’s guidelines and recommendations for HPMC grades suitable for high water retention in dry-mix mortars. They often provide technical data sheets and application advice to help you make an informed choice.

The selected HPMC grade must be tested in your specific dry-mix mortar formulation to ensure it meets your desired water retention requirements and delivers the desired performance. Conducting small-scale trials and evaluating the workability, open time and bonding properties of the mortar can help you verify the effectiveness of your chosen HPMC grade.