How Ready-Mixed Mortar Additives Improve Mortar Performance!

How Ready-Mixed Mortar Additives Improve Mortar Performance!

Modified additives such as ready-mixed mortar additives, cellulose ether, coagulation regulator, redispersible latex powder, air-entraining agent, early strength agent, water reducer, etc., which are added according to the needs of the project, greatly improve the performance of ready-mixed mortar. Physical and mechanical properties.

1. Ready-mixed mortar additive

The anionic surfactant contained in the ready-mixed mortar additive in the project can make the cement particles disperse each other, release the free water encapsulated by the cement aggregate, fully diffuse the aggregated cement mass, and completely hydrate it to achieve a compact structure and increase the mortar density. Strength, improve impermeability, crack resistance and durability. The mortar mixed with ready-mixed mortar additives has good workability, high water retention rate, strong cohesive force, non-toxic, harmless, safe and environmentally friendly during operation. It is suitable for the production of ordinary masonry, plastering, ground, and waterproof mortar in ready-mixed mortar factories. It is used for the masonry and construction of concrete clay bricks, ceramsite bricks, hollow bricks, concrete blocks, unburned bricks in various industrial and civil buildings. Construction of internal and external wall plastering, concrete wall plastering, floor and roof leveling, waterproof mortar, etc.

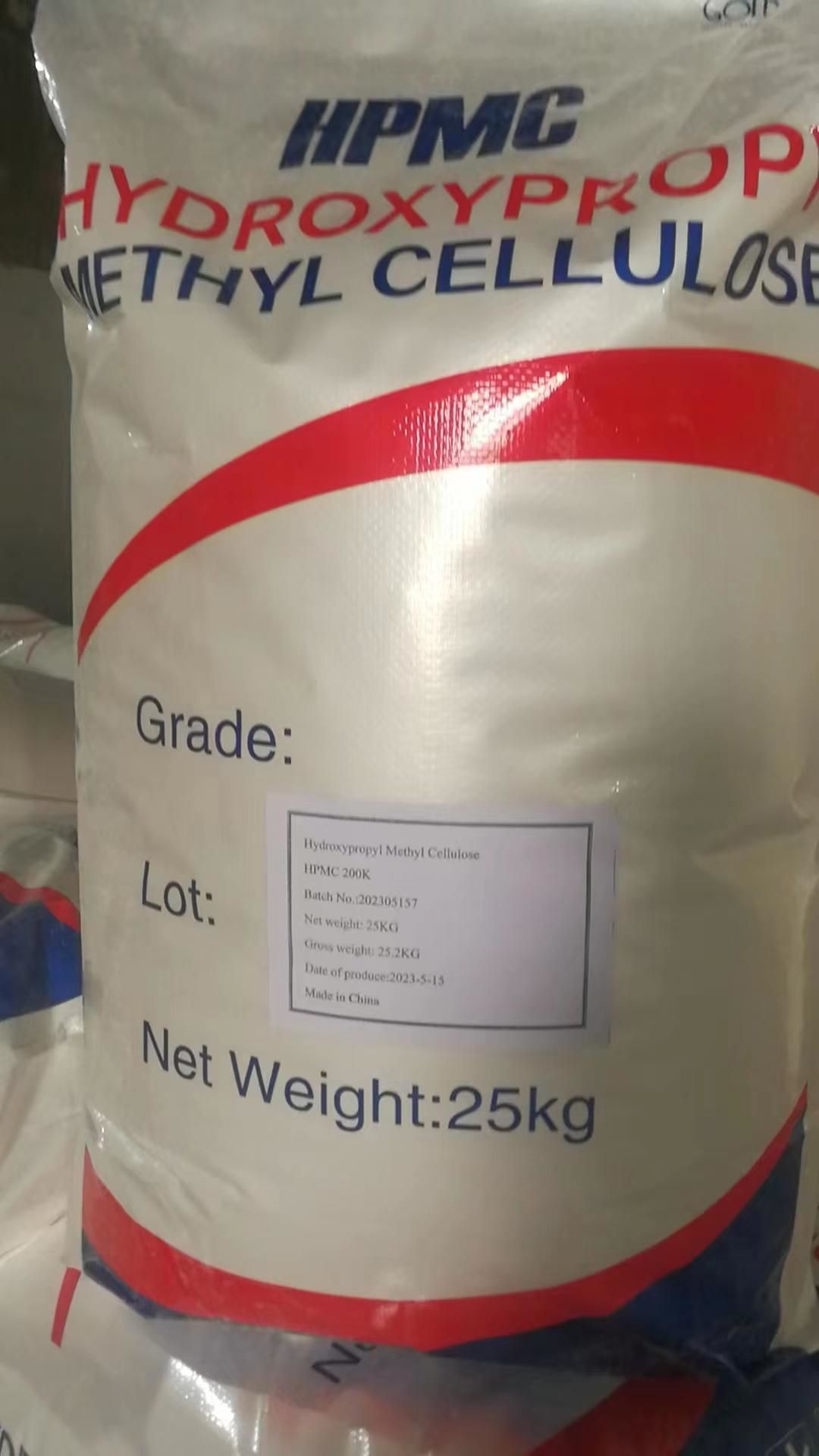

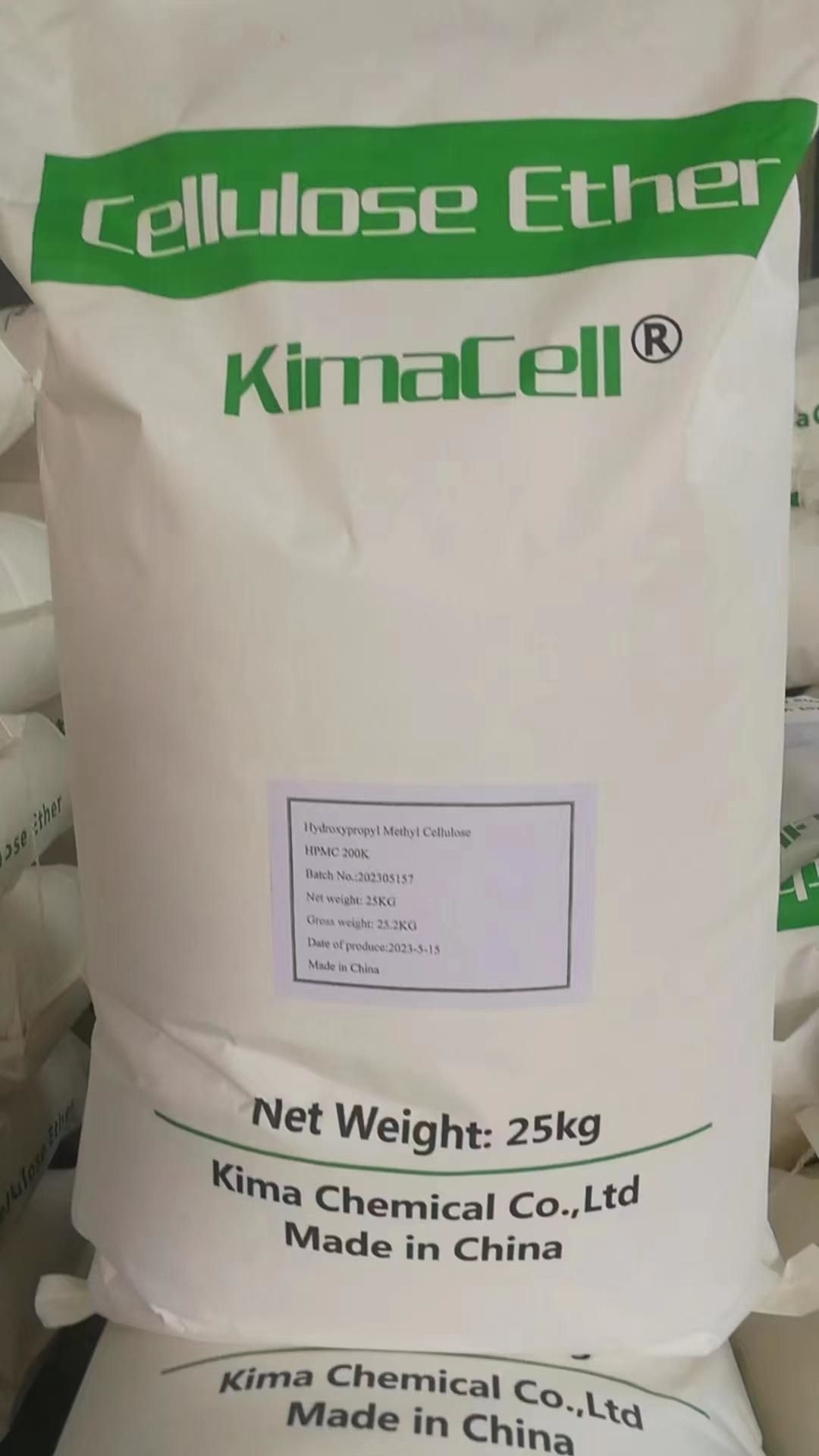

2. Cellulose ether

In ready-mixed mortar, cellulose ether is a main additive that can significantly improve the performance of wet mortar and affect the construction performance of mortar. Reasonable selection of cellulose ethers of different varieties, different viscosities, different particle sizes, different degrees of viscosity and added amounts will have a positive impact on the improvement of the performance of dry powder mortar.

The production of cellulose ether is mainly made of natural fibers through alkali dissolution, grafting reaction (etherification), washing, drying, submersion and other processes. In the production of building materials, especially dry powder mortar, cellulose ether plays an irreplaceable role, especially in the production of special mortar (modified mortar), it is an indispensable and important component. Cellulose ether plays the role of water retention, thickening, delaying cement hydration power, and improving construction performance. Good water retention capacity makes cement hydration more complete, can improve the wet viscosity of wet mortar, increase the bonding strength of mortar, and adjust the time. Adding cellulose ether to mechanical spraying mortar can improve the spraying or pumping performance and structural strength of the mortar. Therefore, cellulose ether is being widely used as an important additive in ready-mixed mortar. The cellulose ethers used in ready-mixed mortar are mainly methyl hydroxyethyl cellulose ether and methyl hydroxypropyl cellulose ether. , they occupy more than 90% of the market share.

3. Redispersible latex powder

Redispersible latex powder is a powdery thermoplastic resin obtained by spray drying and subsequent processing of polymer emulsion. It is mainly used in construction, especially dry powder mortar to increase cohesion, cohesion and flexibility.

The role of redispersible latex powder in mortar: redispersible latex powder forms a film after dispersion and acts as a second adhesive to enhance adhesion; the protective colloid is absorbed by the mortar system and will not be destroyed by water after film formation Or two dispersions; the film-forming polymer resin is distributed throughout the mortar system as a reinforcing material, thereby increasing the cohesion of the mortar.

Redispersible latex powder in wet mortar can improve construction performance, improve flow performance, increase thixotropy and sag resistance, improve cohesion, prolong open time, enhance water retention, etc. After the mortar is cured, it can improve tensile strength. Tensile strength, enhanced bending strength, reduced elastic modulus, improved deformability, increased material compactness, improved wear resistance, improved cohesive strength, reduced carbonization depth, reduced water absorption of the material, and made the material have excellent water repellency Water-based and other effects.

4. Air-entraining agent

Air-entraining agent, also known as air-entraining agent, refers to the introduction of a large number of uniformly distributed micro-bubbles during the mortar mixing process, which can reduce the surface tension of the water in the mortar, resulting in better dispersion and reduced mortar mixture. Bleeding, segregating additives. In addition, the introduction of fine and stable air bubbles also improves the construction performance. The amount of air introduced depends on the type of mortar and the mixing equipment used.

Although the amount of air-entraining agent is very small, the air-entraining agent has a great influence on the performance of ready-mixed mortar, which can effectively improve the workability of ready-mixed mortar, improve the impermeability and frost resistance of mortar, and reduce the density of mortar , save materials and increase the construction area, but the addition of air-entraining agent will reduce the strength of the mortar, especially the compressive mortar. Correlation intensity to determine the optimal dosage.

5. Early strength agent

The early strength agent is an additive that can accelerate the development of the early strength of the mortar, most of which are inorganic electrolytes, and a few are organic compounds.

The accelerator for ready-mixed mortar is required to be powdery and dry. Calcium formate is the most widely used in ready-mixed mortar. Calcium formate can improve the early strength of mortar, and accelerate the hydration of tricalcium silicate, which can reduce water to a certain extent. Moreover, the physical properties of calcium formate are stable at room temperature. It is not easy to agglomerate and is more suitable for application in dry powder mortar.

6. Water reducer

Water reducing agent refers to the additive that can reduce the amount of mixing water under the condition of keeping the consistency of the mortar basically the same. The water reducer is generally a surfactant, which can be divided into ordinary water reducers, high efficiency water reducers, early strength water reducers, retarded water reducers, retarded high efficiency water reducers and induced water reducers according to their functions. .

The water reducer used for ready-mixed mortar is required to be powdery and dry. Such a water reducer can be evenly dispersed in the dry powder mortar without reducing the shelf life of the ready-mixed mortar. At present, the application of water reducing agent in ready-mixed mortar is generally in cement self-leveling, gypsum self-leveling, plastering mortar, waterproof mortar, putty, etc. The choice of water reducing agent depends on different raw materials and different mortar properties. Choose.