What is Tio2 ?

What is Tio2 ?

TiO2, often abbreviated from Titanium dioxide, is a versatile compound with a wide range of applications across various industries. This substance, composed of titanium and oxygen atoms, holds significance due to its unique properties and diverse uses. In this comprehensive exploration, we’ll delve into the structure, properties, production methods, applications, environmental considerations, and future prospects of titanium dioxide.

Structure and Composition

Titanium dioxide possesses a simple chemical formula: TiO2. Its molecular structure consists of one titanium atom bonded with two oxygen atoms, forming a stable crystalline lattice. The compound exists in several polymorphs, with the most common forms being rutile, anatase, and brookite. These polymorphs exhibit different crystal structures, leading to variations in their properties and applications.

Rutile is the most thermodynamically stable form of titanium dioxide and is characterized by its high refractive index and opacity. Anatase, on the other hand, is metastable but possesses higher photocatalytic activity compared to rutile. Brookite, though less common, shares similarities with both rutile and anatase.

Properties

Titanium dioxide boasts a plethora of remarkable properties that make it indispensable in numerous industries:

- Whiteness: Titanium dioxide is renowned for its exceptional whiteness, which stems from its high refractive index. This property enables it to efficiently scatter visible light, resulting in bright white hues.

- Opacity: Its opacity arises from its ability to absorb and scatter light effectively. This property makes it a preferred choice for imparting opacity and coverage in paints, coatings, and plastics.

- UV Absorption: Titanium dioxide exhibits excellent UV-blocking properties, making it a key ingredient in sunscreens and UV-resistant coatings. It efficiently absorbs harmful UV radiation, protecting underlying materials from degradation and UV-induced damage.

- Chemical Stability: TiO2 is chemically inert and resistant to most chemicals, acids, and alkalis. This stability ensures its longevity and durability in various applications.

- Photocatalytic Activity: Certain forms of titanium dioxide, notably anatase, demonstrate photocatalytic activity when exposed to ultraviolet (UV) light. This property is harnessed in environmental remediation, water purification, and self-cleaning coatings.

Production Methods

The production of titanium dioxide typically involves two primary methods: the sulfate process and the chloride process.

- Sulfate Process: This method involves the conversion of titanium-containing ores, such as ilmenite or rutile, into titanium dioxide pigment. The ore is first treated with sulfuric acid to produce a titanium sulfate solution, which is then hydrolyzed to form a hydrated titanium dioxide precipitate. After calcination, the precipitate is transformed into the final pigment.

- Chloride Process: In this process, titanium tetrachloride (TiCl4) is reacted with oxygen or water vapor at high temperatures to form titanium dioxide particles. The resulting pigment is typically purer and possesses better optical properties compared to sulfate process-derived titanium dioxide.

Applications

Titanium dioxide finds extensive applications across diverse industries, owing to its versatile properties:

- Paints and Coatings: Titanium dioxide is the most widely used white pigment in paints, coatings, and architectural finishes due to its opacity, brightness, and durability.

- Plastics: It is incorporated into various plastic products, including PVC, polyethylene, and polypropylene, to enhance opacity, UV resistance, and whiteness.

- Cosmetics: TiO2 is a common ingredient in cosmetics, skincare products, and sunscreen formulations due to its UV-blocking properties and non-toxic nature.

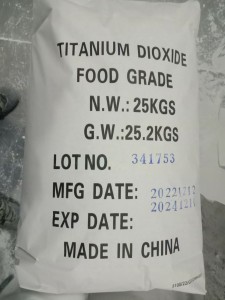

- Food and Pharmaceuticals: It serves as a white pigment and opacifier in food products, pharmaceutical tablets, and capsules. Food-grade titanium dioxide is approved for use in many countries, though concerns exist regarding its safety and potential health risks.

- Photocatalysis: Certain forms of titanium dioxide are utilized in photocatalytic applications, such as air and water purification, self-cleaning surfaces, and pollutant degradation.

- Ceramics: It is employed in the production of ceramic glazes, tiles, and porcelain to enhance opacity and whiteness.

Environmental Considerations

While titanium dioxide offers numerous benefits, its production and use raise environmental concerns:

- Energy Consumption: The production of titanium dioxide typically requires high temperatures and significant energy inputs, contributing to greenhouse gas emissions and environmental impact.

- Waste Generation: Both sulfate and chloride processes generate by-products and waste streams, which may contain impurities and require proper disposal or treatment to prevent environmental contamination.

- Nanoparticles: Nanoscale titanium dioxide particles, often used in sunscreen and cosmetic formulations, raise concerns regarding their potential toxicity and environmental persistence. Studies suggest that these nanoparticles may pose risks to aquatic ecosystems and human health if released into the environment.

- Regulatory Oversight: Regulatory agencies worldwide, such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), closely monitor the production, use, and safety of titanium dioxide to mitigate potential risks and ensure compliance with environmental and health regulations.

Future Prospects

As society continues to prioritize sustainability and environmental stewardship, the future of titanium dioxide hinges on innovation and technological advancements:

- Green Manufacturing Processes: Research efforts focus on developing more sustainable and energy-efficient production methods for titanium dioxide, such as photocatalytic and electrochemical processes.

- Nanostructured Materials: Advancements in nanotechnology enable the design and synthesis of nanostructured titanium dioxide materials with enhanced properties for applications in energy storage, catalysis, and biomedical engineering.

- Biodegradable Alternatives: The development of biodegradable and eco-friendly alternatives to conventional titanium dioxide pigments is underway, aiming to reduce environmental impact and address concerns surrounding nanoparticle toxicity.

- Circular Economy Initiatives: Implementation of circular economy principles, including recycling and waste valorization, could mitigate resource depletion and minimize the environmental footprint of titanium dioxide production and utilization.

- Regulatory Compliance and Safety: Continued research into the environmental and health effects of titanium dioxide nanoparticles, coupled with robust regulatory oversight, is essential to ensure safe and responsible use across various industries.

In conclusion, titanium dioxide stands as a multifaceted compound with myriad applications and implications. Its unique properties, coupled with ongoing research and innovation, promise to shape its role in diverse industries while addressing environmental concerns and fostering sustainable practices for the future.