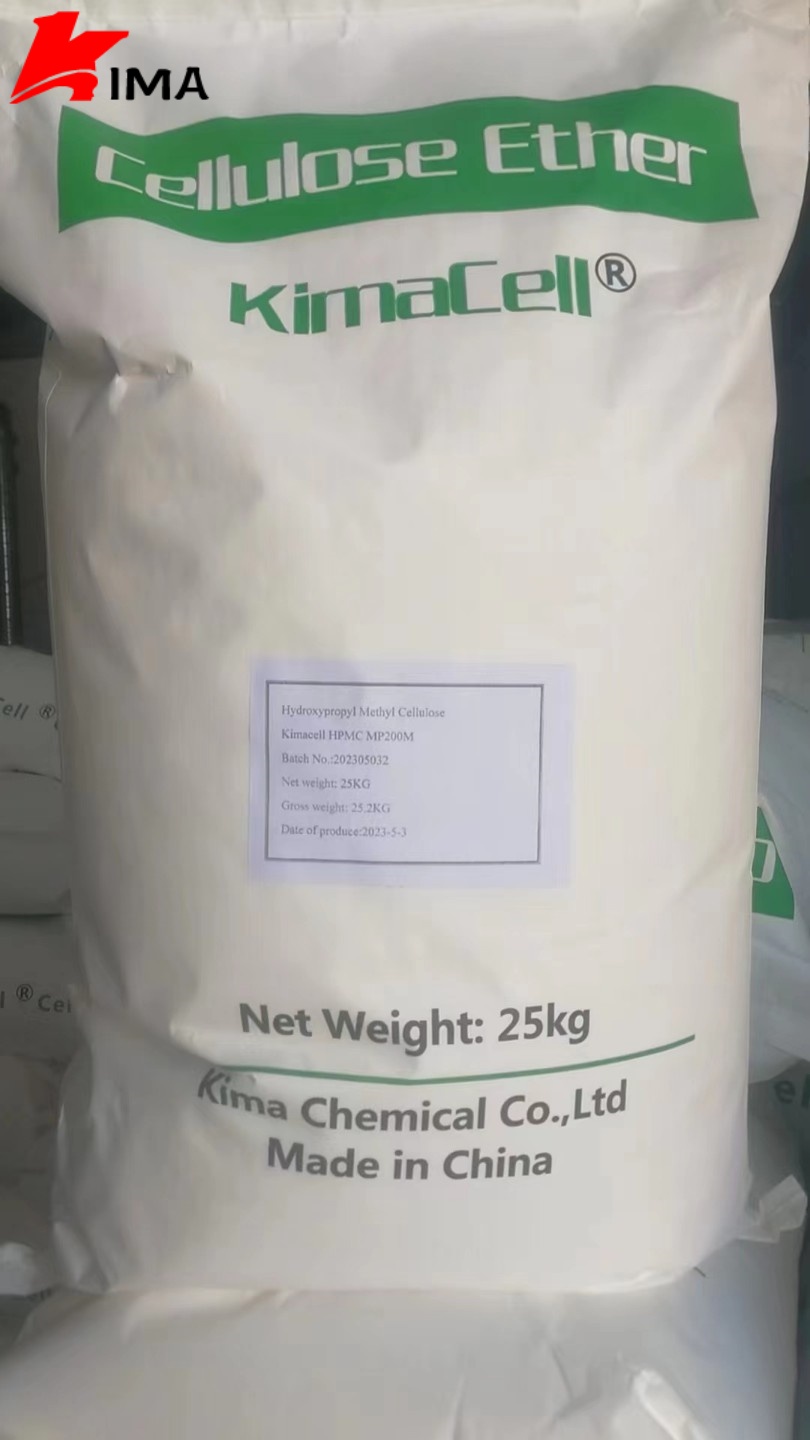

(Hydroxypropyl)methyl cellulose | CAS 9004-65-3

(Hydroxypropyl)methyl cellulose | CAS 9004-65-3

(Hydroxypropyl)methyl cellulose, also known by its abbreviation HPMC or its CAS number 9004-65-3, is a cellulose ether derived from natural cellulose. It is a semi-synthetic polymer that is widely used in various industries due to its unique properties and versatility. Here’s a closer look at this compound:

Structure and Properties:

1 Structure: HPMC is synthesized through the chemical modification of cellulose, where both methyl (-CH3) and hydroxypropyl (-CH2CHOHCH3) groups are introduced onto the cellulose backbone.

2 Degree of Substitution (DS): The degree of substitution refers to the average number of substituent groups per glucose unit in the cellulose chain. It determines the properties of HPMC, such as solubility, viscosity, and film-forming ability.

3 Properties: HPMC exhibits properties such as thickening, water retention, film formation, and surface activity. The properties can be adjusted by controlling the DS during synthesis.

Production:

1.Cellulose Sourcing: Cellulose, the primary raw material for HPMC, is sourced from renewable sources like wood pulp or cotton.

Etherification: Cellulose undergoes etherification, where it is reacted with propylene oxide to introduce hydroxypropyl groups and then with methyl chloride to add methyl groups.

2.Purification: The modified cellulose is purified to remove impurities and by-products, resulting in the final HPMC product.

Applications:

3.Construction Industry: HPMC is widely used in construction materials such as cement-based mortars, plasters, and tile adhesives to improve workability, water retention, and adhesion.

4.Pharmaceuticals: It serves as a binder, thickener, film former, and stabilizer in pharmaceutical formulations including tablets, capsules, ophthalmic solutions, and topical creams.

5.Food Industry: HPMC acts as a thickener, stabilizer, and emulsifier in various food products such as sauces, dressings, ice creams, and baked goods.

6.Cosmetics and Personal Care: In cosmetics and personal care products, HPMC is used as a thickener, suspending agent, film former, and moisturizer in creams, lotions, shampoos, and gels.

7.Paints and Coatings: It enhances the viscosity, sag resistance, and film formation properties of water-based paints, adhesives, and coatings.

Conclusion:

(Hydroxypropyl)methyl cellulose, with its diverse range of applications and advantageous properties, is a crucial ingredient in many industrial and commercial products. Its role in enhancing the performance, stability, and functionality of various formulations makes it indispensable across multiple sectors. As industries continue to innovate, the demand for HPMC is expected to persist, driving further advancements in its production methods and applications.